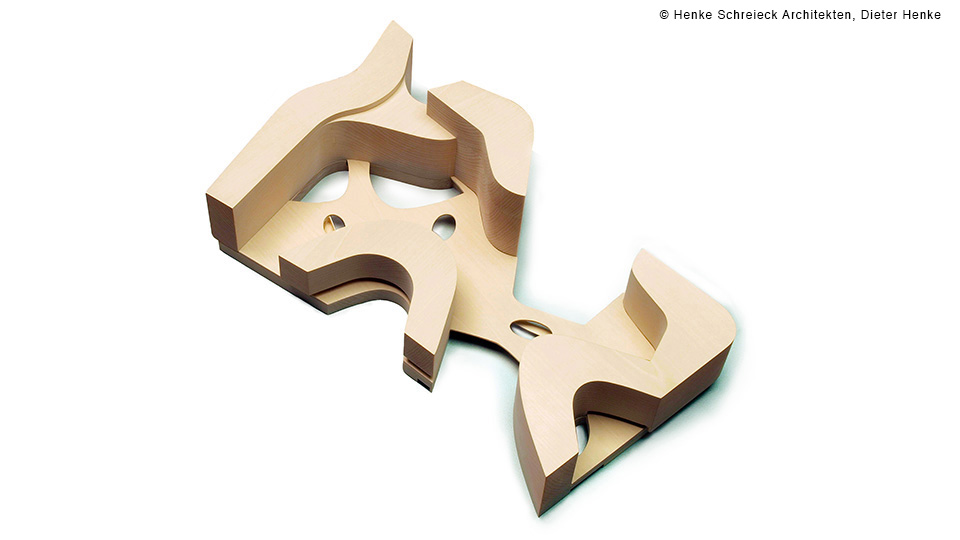

Sketch of the Erste Campus, the Erste Group’s new headquarters in Vienna. It was the architects Henke Schreieck’s goal to create a building with an organic, natural design.

Project report Erste Campus Vienna.

A curvy challenge.

Project report Erste Campus Vienna.

A curvy challenge.

Developing the Erste Campus was a real challenge. The curve-shaped building required drainage channels with corresponding grates.

Here you can see the building’s irregular shape. How to install regular, straight channel bodies and grates with this curved shape? Simply cutting regular grates to fit would damage the galvanizing...

This is where BG’s support and engineering stepped in. Individual layout plans were created for all channels and angles. As you can tell from the size of the building, there were quite a few...

These were used as a basis for technical drawings. In a number of steps, individually fitted grates were handcrafted and galvanized – for a total of 200 channel bodies installed on different levels…

An extremely efficient drainage system perfectly adjusted to the building’s curved shape was created. Elegance and functionality in perfect harmony.

Sketch of the Erste Campus, the Erste Group’s new headquarters in Vienna. It was the architects Henke Schreieck’s goal to create a building with an organic, natural design.

Developing the Erste Campus was a real challenge. The curve-shaped building required drainage channels with corresponding grates.

Here you can see the building’s irregular shape. How to install regular, straight channel bodies and grates with this curved shape? Simply cutting regular grates to fit would damage the galvanizing...

This is where BG’s support and engineering stepped in. Individual layout plans were created for all channels and angles. As you can tell from the size of the building, there were quite a few...

These were used as a basis for technical drawings. In a number of steps, individually fitted grates were handcrafted and galvanized – for a total of 200 channel bodies installed on different levels…

An extremely efficient drainage system perfectly adjusted to the building’s curved shape was created. Elegance and functionality in perfect harmony.

However, there’s more to the complex than its looks. Its development was a real challenge for the architects Henke Schreieck, who were responsible for the planning and the construction. As an example, they had to install drainage channels with grates all around the curve-shaped building and the terraces. After all, regular channel bodies are straight, not curved, and so are the grates...

A curve-shaped building poses a lot of problems – for example: what about drainage channels?

In order to meet this challenge, the project was put out for tender. Who can provide individual channel bodies and grates for our organically shaped building that also meet the claim of sustainability? These were the architects’ requirements. Three manufacturers applied – and BG was awarded the contract.

Their concept combined the excellent characteristics of the BG channel systems with our competent and comprehensive support.

Different channels made from our outstanding FILCOTEN® materials were installed, combining maximum eco-friendliness with excellent performance. This is particularly important with regard to compressive strength as well as temperature resistance and fire protection. In addition, our high-quality steel channels were also installed – their clever design offers a powerful solution for terrace and window areas.

The construction company in charge of the project started by mitering the channel bodies to prepare for the curve-shaped installation. Then the galvanized – and therefore rust-proof – grates were fitted. Simply cutting the grates to fit would damage the galvanizing, causing them to rust within the shortest time.

BG-Support at its best: 200 individually shaped and fully galvanized, tailor-made grates.

This is where BG’s support and engineering stepped in. Our technicians created individual layout plans for all gutters and angles. These were used as a basis for technical drawings. In a number of steps, individually fitted grates were handcrafted and galvanized – for a total of 200 channel bodies Thanks to a detailed plan, the installation was flawless. The result: Highly efficient channel bodies with corrosion-resistant, tailor-made grates.

Ready for the next challenge.

An extremely efficient drainage system perfectly adjusted to the building’s curved shape was created. Elegance and functionality in perfect harmony.

In the end, there is only one thing left to say: The BG Group would like to thank the architects Henke Schreieck for their trust and for creating this fabulous complex. Whenever you face another challenge, you know where to find us. Whenever you face another challenge, you know where to find us.

style="color: #9ed300">Project profile

Project name

Project report Erste Campus Vienna.

Location

Vienna, Austria

Challenge

Challenge: Enabling maximum sustainability of the building

Installed channel types

BG-FILCOTEN® light mini

BGFILCOTEN® light

BG-FILCOTEN® pro

steel channels BG-FA unilaterally perforated

Total running meters

over 2000

Servicesby BG-Support

Services by BG-Support: On-site measurements, creating technical drawings, development of special solutions

Specialchallenge

Special challenge: A circular building with straight channel bodies, including grates. Individually manufacturing and installing 200 fully galvanized custom grates.

Builder

Builder: Erste Campus Immobilien GmbH & Co KG

BG-Support-Team

Krexhammer Valentin Wieninger, Peter Ablinger, Christian

BG trading partners

Quester, Wiener Neustadt

Architects

Henke Schreieck Architekten ZT GmbH

Building contractor

Granit Oeynhausen

Valentin Krexhammer

Sales Management

BG-Graspointner | Austria