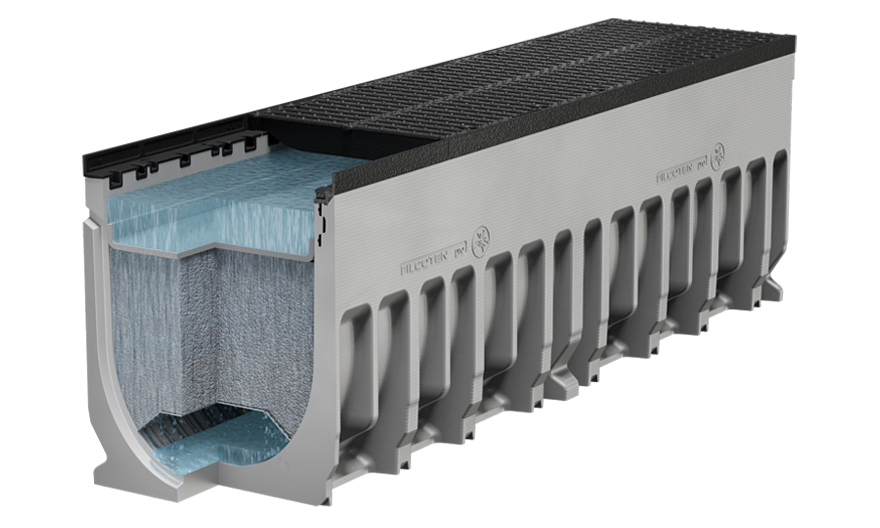

In certain areas, rainwater cannot seep directly into the ground due to sealed surfaces. Substrate channels such as the new FILCOTEN® green absorb and clean rainwater on connected surfaces, letting it seep into the ground.

The new BG-FILCOTEN green

Higher, faster, cleaner.

The new BG-FILCOTEN green

Higher, faster, cleaner.

The direct way back to nature

In the natural water cycle, precipitation ideally seeps directly into the ground. In reality, however, this is faced with three challenges.

• Due to increasing population, there are more and more sealed surfaces. Rainwater cannot simply seep into the ground, it has to be redirected using drainage systems. In many urban areas, this lowers the groundwater level.

• In industrial areas, precipitation contains more impurities and contaminants due to the pollution of the air.

• Not to forget road traffic and the resulting dust, salts and tire wear particles.

It is prohibited by official standards in certain states and counties and also highly questionable from an ecological standpoint – to simply discharge polluted water into the ground. Furthermore, precipitation is likely to increase in the future and the sewers are already unable to cope with redirecting water to the treatment plants today. Substrate channels absorb and filter rainwater, re-entering it into the natural water cycle by letting it seep into the ground.

New standard, new substrate

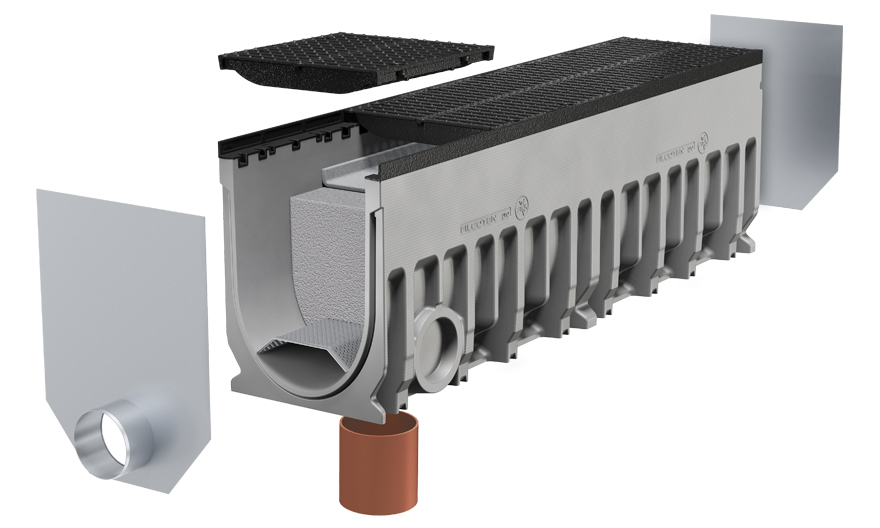

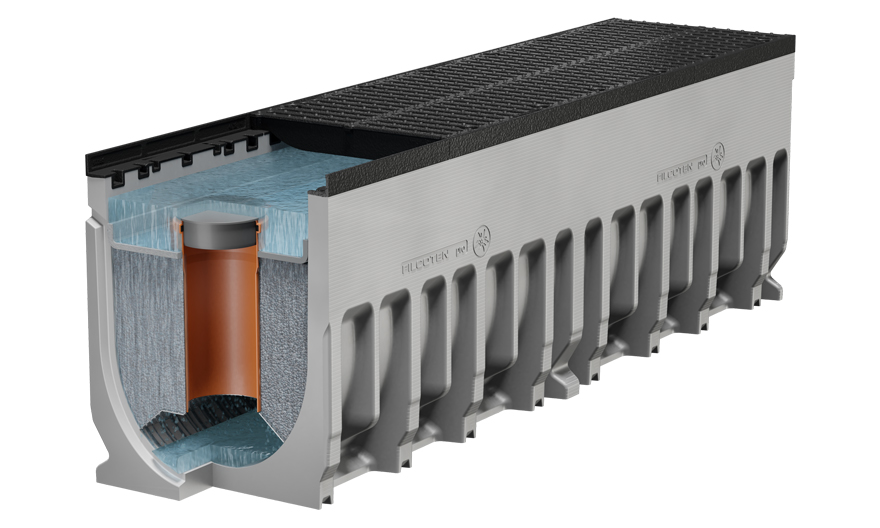

In line with the stricter requirements for technical filters, the necessary substrate thickness has increased from 150 to 300 mm. Thanks to this, the new BG-FILCOTEN® green has even more efficient cleaning properties at a high seepage rate. The newly developed technical filter of the highest cleaning category is now not only applicable for water on fortified surfaces, but also for precipitation draining from zinc or cooper roofs.

Large quantities? No problem!

In the first five to fifteen minutes of very intense rainfall, the water quantities can be too much for the filter to absorb. To meet these peak quantities, the excess amounts are initially stored within the drainage channel, which allows the water to simply trickle down bit by bit. This process is called retention. The new BG-FILCOTEN® green comes with a significantly increased retention volume directly beneath the intake screen. In this way, it can move greater amounts of rainwater to the outer edges without backing up, draining even larger surfaces than before. Another advantage: The water pressure and with it the seeping speed increase with higher volumes of water. The expansion of the nominal diameter from 300 to 400 mm also increases the connecting area per running meter of the drainage channel.

| Connecting areas per running meter of the drainage channel: | |

| Connectable areas [sqm] | Rain intensity [l/s*Ha] |

| 87 | 150 |

| 65 | 200 |

| 52 | 250 |

| 43 | 300 |

| 37 | 350 |

Three-way cleaner

The new BG-FILCOTEN® green combines tried and tested strengths with the latest technology. It offers exceptional cleaning properties and sustainability when it comes to raw materials, manufacture and application.

• raw materials

Just like its predecessor, the drainage channel body is made from FILCOTEN® HPC (High Performance Concrete), based on 100 % recyclable, mineral raw materials, completely free from solvents or resins.

• Manufacture

By excluding solvents and resins, we take responsibility for our employees and protect them from harmful evaporation. In addition, the production process is based entirely on wind, water and other ecological energy sources.

• Application

BG-FILCOTEN® green is the go-to solution when cleaning is simply not enough. This applies to industrial buildings, condominiums with parking facilities, logistics centers and houses with zinc or copper roofs in particular. The new technical filter with its effective spectrum lives up to these challenges. The prefilter fleece above the substrate can be easily installed and replaced, providing efficient preclearing of coarse dirt to ensure the longevity of the substrate.