- Enhanced anchoring performance in levelling concrete

- Optimised structural safety

- Wide channel foot for solid positioning of the gutter, even during installation

- Due to its very construction, the required grouting joint automatically materialises when installing in curb stone areas or upright areas

- The upper 90 mm of the channel wall are vertical in order to enable ideal working with pavement covering

BG-FILCOTEN® one urban Trench Drain

Technical data

Application areas: Platform National Road Fire Station Airport (landside) Pedestrian zones Landscape construction District Road Country lane Parking (car) Pavers Cycling routes Rest area Sports facility

Well

thought-out system,

outstanding performance.

Sump unit, one part

- Suspended silt bucket for sump unit

- Total length 500 mm

- closed base

- Outlet NW 100 / 150 with DN 150; NW 200 with DN 200 (pipe coupling)

- Left/right rotation

- Maintenance access in the style of the channel run

One grating – one design

- continuation of the slotted grating design also for the cast iron grating

- Edge and grating, cathodic dip-coated

- fix-locking as well as 4 point bolted system

- Class D 400

Retention & stepped slope

- Overall height 40-0 (20 cm higher than no 0) – for greater hydraulic performance

- Longer channel runs possible up to one outlet point

- Suitable for retention (additional volume: 40 l/m)

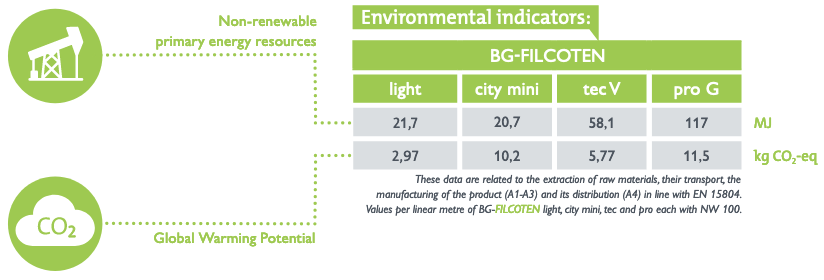

Lived sustainability: FILCOTEN® HPC (High Performance Concrete)

- Mineral high-performance concrete

- Extremely durable, stable and UV-resistant

- Extremely resistant to frost, de-icing salt, oil, petrol

- Verified LCA (life cycle assessment) according to ISO 14040 & ISO 14044 as well as 15804

- Manufactured with 100% green energy

- IBR[1] certified, tested for: VOCs, styrene and BTEX, heavy metals, radioactivity

- certified³⁾ in acc. with KIWA BRL 5070

- 100% recyclable quality class U-A[2]

[1] Meets the strict criteria outlined by the Rosenheim Institute for Construction Biology (IBR)

[2] Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)).

Maintenance unit

- Maintenance access in the style of the channel run

- T-piece with knock-out section (optional)

- Total length 1000 mm

- closed base

Outlet unit

- Outlet unit NW 100 with DN 100; NW 150 with DN 150 and NW 200 with DN 200 opening available.

- The drainpipe can be serviced/cleaned through the removable grating.

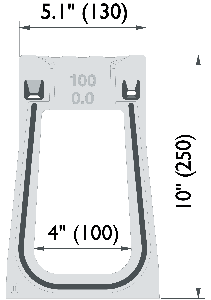

Basic channel

- NW 100, NW 150 or NW 200

- Standard construction height no 0

- Total length 1,000 mm

Sump unit, upper part

- Simple cleaning of the outlet unit

- Large outlet opening in the channel bottom

- Suspended silt bucket for sump unit

- T-piece with knock-out section (optional)

- Total length 1,000 mm

Front cap

- interlocking

- Closure of front sides of the channel run

End cap with outlet

- interlocking

- Closure of the run with sealed socket (pipe coupling) NW 100: DN 100; NW 150: DN 150; NW 200: DN 200

sump unit, bottom part

- - socket (pipe coupling) NW 100 / 150: DN 150; NW 200: DN 200

- Left/right rotation

Monolithic,

versatile, unique.

Tenon system for non-directional installation

- Non-directional channel joint for easy and fast installation

- Interlocking tenon system for snug, truly-aligned positioning of elements

- Predefined distance in the joint for optimum function of the insertable sealing profile

Cyclist- and pedestrian-friendly

Monolithic structure

Optimised inlet surface

Inlet opening in the channel joint

High-performance

At one with the surrounding environment

- Fine finished concrete colour and surface quality

A sealing system1) which is easy to use

1) Optional sealing profile.

At one with the surrounding environment

Multiple certifications

1) Quality class U-A (certified by the experimental and research Institute for construction Salzburg)

2) No use of synthetic resins.

3) KIWA certificate number: NL BSB® K43940.

BG-FILCOTEN

when opposites

attract great things

FILCOTEN HPC (High Performance Concrete) is a material that unites outstanding technical properties with ecological sustainability. The optimised high-density structure of HPC makes it possible to construct extremely stable lightweight drainage channels – but it’s the idea behind it that makes it unique.

Unique concept, revolutionary results.

Our engineers wanted to bring together two extremes:

maximum performance with minimum environmental impact.

Maximum performance, minimal environmental impact.

After intensive development, they finally achieved their goal. FILCOTEN HPC

embodies these opposites, making it unique in the market.

Technology

- FILCOTEN HPC enables lightweight construction

- Quick and easy to lay

- Dimensionally stable, robust concrete elements

- Unsurpassed stability and durability

- Exceptional pressure resistance, well above the requirements in EN 1433

- Maximum resistance to frost and de-icing salt

- UV resistant

- Non-combustible construction material – Class A1

- so no harmful smoke development

- Ideal coefficient of expansion, identical to that of the surrounding concrete

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

Sustainability

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

- Manufactured with 100% green power

- Resource-efficient manufacturing process

- 100% recyclable, certified

- Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)).

- Environmental & energy management certified under ISO 14001/50001 at the location in Oberwang, Austria

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity, styrene-free

Any

questions?