BG-FILCOTEN® connect cable duct

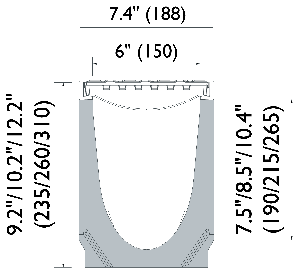

Technical data

Application areas: Industrial Cable shaft Cable route Sports facility Garage Commercial Lobby

| Features | Weight | Item no. | ||

|---|---|---|---|---|

| front cap | ||||

| BG-FILCOTEN, front cap NW150 (6"), closed, galvanized (light, tec, pro No. 0-10, pro mini H170) Material: galvanised steel |

0.6 kg

1.2 lb | 19015230 | |

| installation chairs | ||||

BG-FILCOTEN SET, composite installation support kit NW100 (4") to NW300 (12") Material: Plastic |

0.7 kg

1.5 lb | 19000401 | ||

| bolting-material | ||||

BG-FILCOTEN, locking device kit complete BG-FILCOTEN pro G - M8, V (NW100-200 (4"-8")) consisting of: 1 piece 32101 Cage nut M8-140-47, galvanized, panel thickness 4,1 mm + 1 piece 32102 Screw M8x25 mm, black-galvanized (DIN 6921) Material: galvanised steel |

0.1 kg

0.1 lb | 32103 | ||

BG-FILCOTEN, locking device kit complete BG-FILCOTEN pro G - M8, STAINLESS STEEL (NW100-200 (4"-8")) consisting of: 1 piece 32107 cage nut M8-140-47, V2A, panel thickness 4,1 mm + 1 piece 32108 Screw M8x25mm, stainless steel V2A (DIN 6921) Material: stainless steel 1.4301 |

0.1 kg

0.1 lb | 32109 | ||

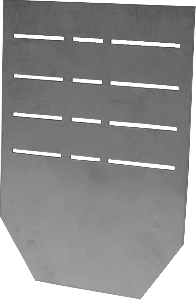

| cable support | ||||

BG-FILCOTEN, cable support NW150 (6"), 1000/108/25, MW31/31, GFK (pro) Mesh width: 31/31 (1.23"/1.23") Material: GRP |

1.2 kg

2.7 lb | 19015410 | ||

Brochures

Spec. Sheets | |

|---|---|

| BG-FILCOTEN connect | |

| FCT-connect-NW150-cast-iron-rail--Spec-sheet--Trench-drain-Accessories-Cover.pdf | |

| FCT-connect-NW150-cast-iron-rail--Spec-sheet--Trench-drain-Accessories-Cover.dwg | DWG |

Product Drawings | |

|---|---|

| BG-FILCOTEN connect | |

| TD-10615162-FCT-pro-G-NW150-Nr.10-0.pdf | |

| TD-10615162-FCT-pro-G-NW150-Nr.10-0.dwg | DWG |

BIM (Building Information Modeling) | |

|---|---|

| 1-BIM-REVIT.zip | ZIP |

| 2-BIM-open-source.zip | ZIP |

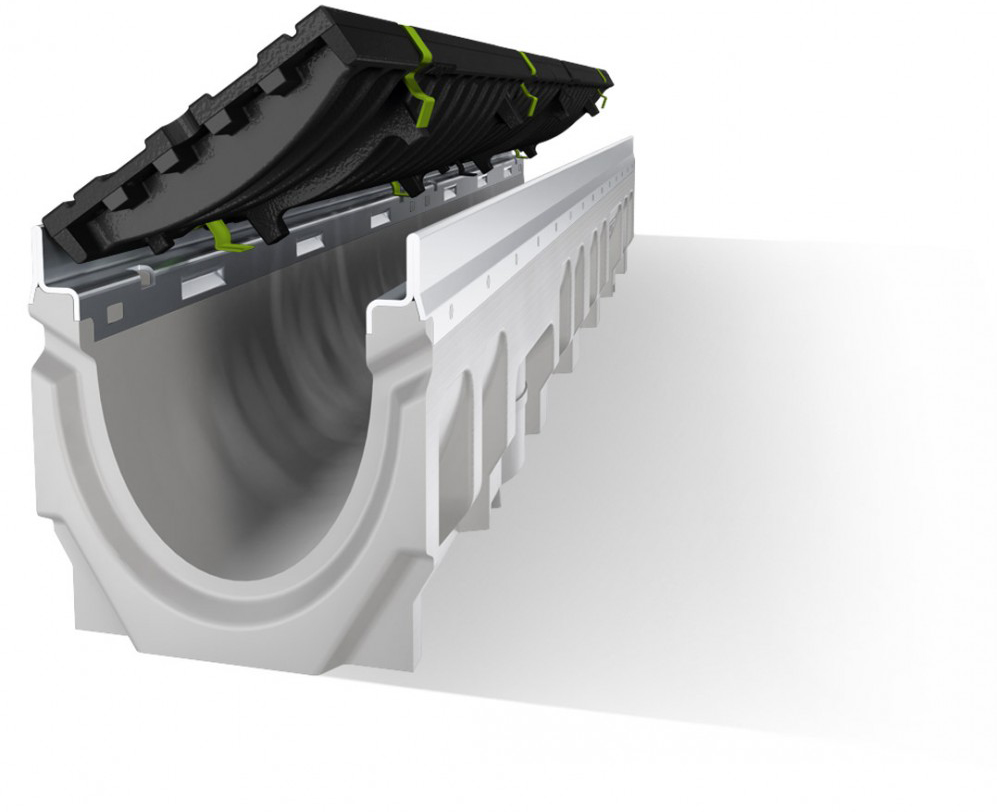

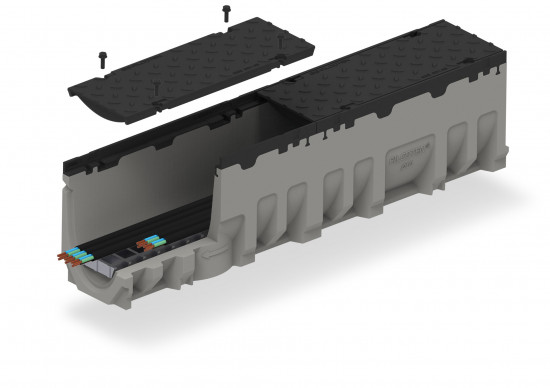

Cable spaghetti?

Not with us ...

Sturdy, maintenance-free, efficient:

BG-FILCOTEN ® connect

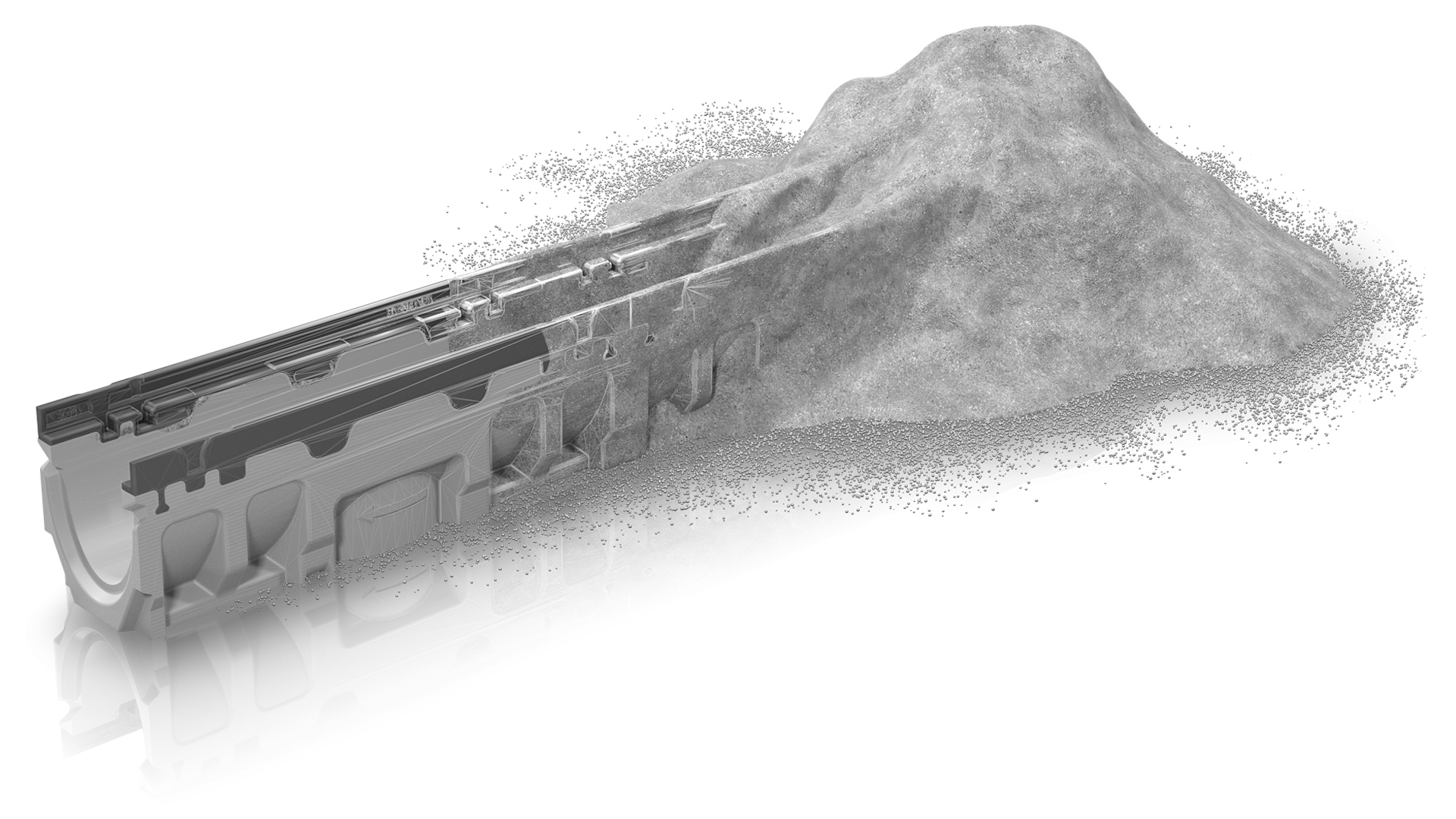

Closed cover

- Class E 600 kN

- with anti-slip surface

- suitable for fork-lift trucks

Functional cable support

- Provides dry support for cables used outdoors should rain ever seep into the system

- Electrically non-conductive due to plastic construction

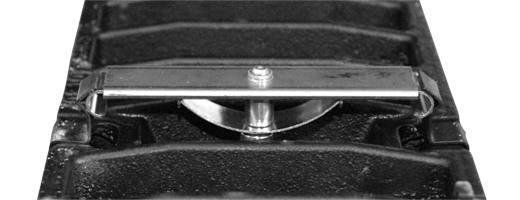

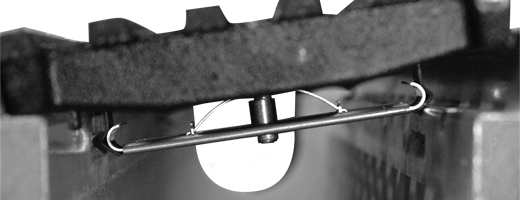

Grating lock

- Integrated fix-locking for quick and easy removal of the grating

- Bolt connections optionally available (8 per metre) where the load strain and safety demands are higher

Sturdy trench drain body

- Made of innovative FILCOTEN® HPC ( High Performance Concrete)

- Lightweight, robust and durable

- High volume for complete cable laying flexibility

- With solid ductile iron edge

Advantages at a glance

- Sturdy, lightweight and durable thanks to the FILCOTEN® HPC

- Bolt-mounted grating; nuts and bolts replaceable

- Non-conductive due to use of GFR ¹⁾ in the cable support

- Ideal for exhibition and event halls as well as for factory premises and production plants

BG-FILCOTEN

when opposites

attract great things

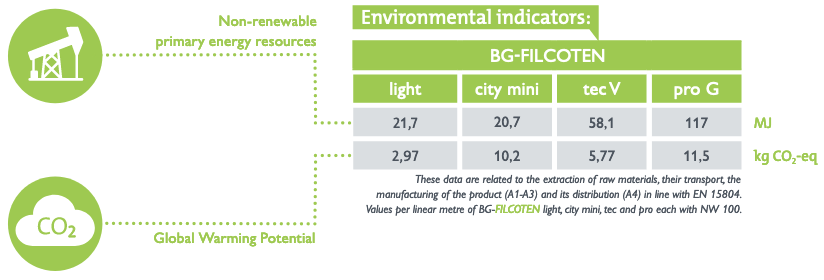

FILCOTEN HPC (High Performance Concrete) is a material that unites outstanding technical properties with ecological sustainability. The optimised high-density structure of HPC makes it possible to construct extremely stable lightweight drainage channels – but it’s the idea behind it that makes it unique.

Unique concept, revolutionary results.

Our engineers wanted to bring together two extremes:

maximum performance with minimum environmental impact.

Maximum performance, minimal environmental impact.

After intensive development, they finally achieved their goal. FILCOTEN HPC

embodies these opposites, making it unique in the market.

Technology

- FILCOTEN HPC enables lightweight construction

- Quick and easy to lay

- Dimensionally stable, robust concrete elements

- Unsurpassed stability and durability

- Exceptional pressure resistance, well above the requirements in EN 1433

- Maximum resistance to frost and de-icing salt

- UV resistant

- Non-combustible construction material – Class A1

- so no harmful smoke development

- Ideal coefficient of expansion, identical to that of the surrounding concrete

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

Sustainability

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

- Manufactured with 100% green power

- Resource-efficient manufacturing process

- 100% recyclable, certified

- Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)).

- Environmental & energy management certified under ISO 14001/50001 at the location in Oberwang, Austria

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity, styrene-free

Any

questions?