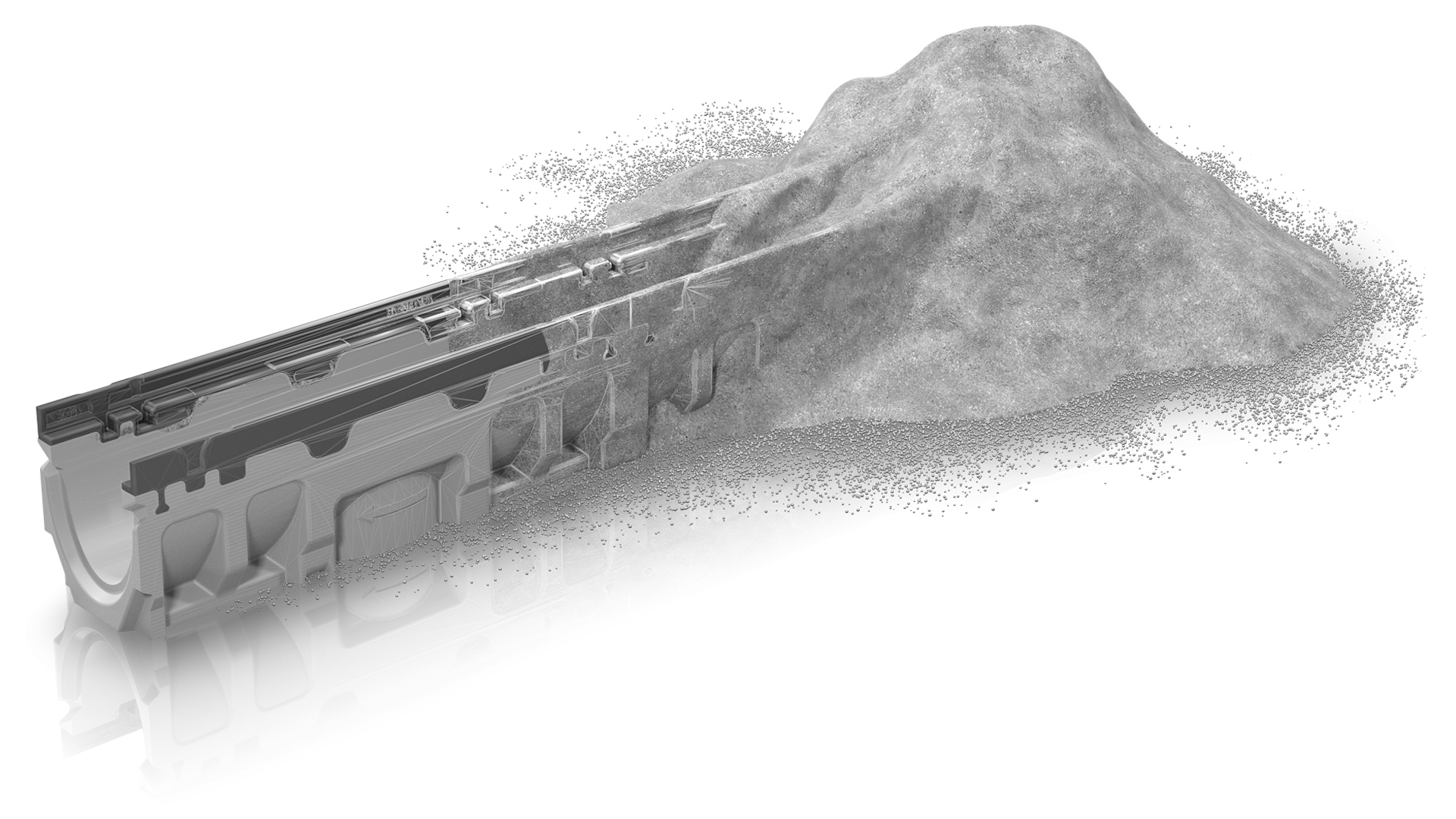

BG-FILCOTEN® one trench drain

Technical data

Application areas: Motorway National Road Container Terminal Road drainage Fire Station Airport (taxiway) Airport (landside) Harbor Industrial District Road Warehouse Country lane Logistics area Parking (truck) Rest area Racetrack Heavy-duty Garage

| Features | Weight | Item no. | ||

|---|---|---|---|---|

| maintenance unit | ||||

BG-FILCOTEN, one maintenance-unit NW 200 No. 0, L=1000mm, incl. ductile iron grate, F900, Type M, without slope consisting of: 1 x 12020180 - concrete part 1 x 17520101 - ductile iron grate 4 x 32110 - bolting material consisting of: 32106 cage nut M10, galv. and 32036 safety screw M10x35, black-galv. Slot width: 23/70 Material: FILCOTEN HPC |

101 kg

222.7 lb | 15020180 | ||

BG-FILCOTEN, one maintenance-unit NW 200 No. 40-0, L=1000mm, incl. ductile iron grate, F900, Type M, without slope consisting of: 1 x 12020188 - concrete part 1 x 17520101 - ductile iron grate 4 x 32110 - bolting material consisting of: 32106 cage nut M10, galv. and 32036 safety screw M10x35, black-galv. Slot width: 23/70 Material: FILCOTEN HPC |

133 kg

293.3 lb | 15020188 | ||

| outlet element | ||||

BG-FILCOTEN, one sump-unit upper-part NW 201 No. 0, L=1000mm, incl. ductile iron grate, F900, Type M, without slope consisting of: 1 x 12020170 - concrete part 1 x 17520101 - ductile iron grate 4 x 32110 - bolting material consisting of: 32106 cage nut M10, galv. and 32036 safety screw M10x35, black-galv. Slot width: 23/70 Material: FILCOTEN HPC |

96 kg

211.7 lb | 15020170 | ||

BG-FILCOTEN, one sump-unit upper-part NW 201 No. 40-0, L=1000mm, incl. ductile iron grate, F900, Type M, without slope consisting of: 1 x 12020178 - concrete part 1 x 17520101 - ductile iron grate 4 x 32110 - bolting material consisting of: 32106 cage nut M10, galv. and 32036 safety screw M10x35, black-galv. Slot width: 23/70 Material: FILCOTEN HPC |

128 kg

282.2 lb | 15020178 | ||

BG-FILCOTEN, one outlet-unit NW 201 No. 0, L=1000mm, incl. ductile iron grate, DN 200 drilling, F900, Type M, without slope consisting of: 1 x 15020180 - maintenance-unit 1 x 30002 - surcharge outlet DN 200 Slot width: 23/70 Material: FILCOTEN HPC |

99 kg

218.3 lb | 15020190 | ||

BG-FILCOTEN, one outlet-unit NW 201 No. 40-0, L=1000mm, incl. ductile iron grate, DN 200 drilling, F900, Type M, without slope consisting of: 1 x 15020188 - maintenance-unit 1 x 30002 - surcharge outlet DN 200 Slot width: 23/70 Material: FILCOTEN HPC |

131 kg

288.9 lb | 15020198 | ||

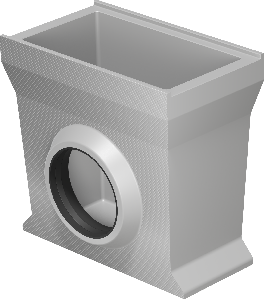

| Outlet unit - lower part | ||||

| BG-FILCOTEN, one outlet-unit base-part NW 201, outlet DN200, F900, Typ M Material: FILCOTEN HPC |

35.5 kg

78.3 lb | 19120095 | |

BG-FILCOTEN, one outlet-unit base-part NW 201, outlet DN300, F900, Typ M Material: FILCOTEN HPC |

39 kg

86 lb | 19120096 | ||

| outlet unit middle part | ||||

BG-FILCOTEN, one outlet-unit middle-part NW 200, F900, Typ M Material: FILCOTEN HPC |

29 kg

64 lb | 19120094 | ||

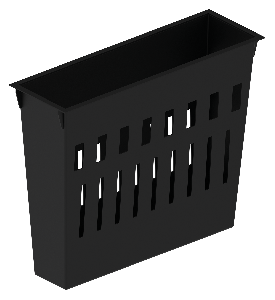

| Silt bucket | ||||

| BG silt bucket for sump unit NW 150, plastic NW 150 - BGU, BGU-Z, BGZ-S and FILCOTEN one NW200 Material: HDPE |

0.7 kg

1.6 lb | 22511 | |

| corner element | ||||

BG-FILCOTEN, one corner-element variable NW 200 No. 0, L=1000mm, SW 23/70mm, F900, Type M, without slope consisting of: 1 x 12020000 - concrete part 2 x 30005 - additional charge mitre cut 1 x 30009 - additional charge bonding Slot width: 23/70 Material: FILCOTEN HPC |

114 kg

251.4 lb | 15020000 | ||

BG-FILCOTEN, one corner-element variable NW 200 No. 40-0, L=1000mm, SW 23/70mm, F900, Type M, without slope consisting of: 1 x 12020008 - concrete part 2 x 30005 - additional charge mitre cut 1 x 30009 - additional charge bonding Slot width: 23/70 Material: FILCOTEN HPC |

142 kg

313.1 lb | 15020008 | ||

| front cap | ||||

| BG-FILCOTEN, one frontplate NW 200, No. 0, closed Material: FILCOTEN HPC |

13 kg

28.7 lb | 19120100 | |

BG-FILCOTEN, one frontplate NW 200, No. 40-0, closed Material: FILCOTEN HPC |

21 kg

46.3 lb | 19120108 | ||

| end cap | ||||

| BG-FILCOTEN, one endplate NW 200, No. 0, outlet DN200 Material: FILCOTEN HPC |

8.5 kg

18.8 lb | 19120110 | |

BG-FILCOTEN, one endplate NW 200, No. 40-0, outlet DN200 Material: FILCOTEN HPC |

16.5 kg

36.4 lb | 19120118 | ||

| adapter cap | ||||

| BG-FILCOTEN, one connectorplate NW 200, No. 0 to 40-0 Material: FILCOTEN HPC |

12.5 kg

27.6 lb | 19120157 | |

| installation chairs | ||||

BG-FILCOTEN SET, composite installation support kit NW100 to NW300 Material: Plastic |

0.7 kg

1.5 lb | 19000401 | ||

| lifting-hook | ||||

| Lifting-hook (consisting of 2 pcs.) for FILCOTEN one NW 200, painted black, max. load with 2 pcs.: 300 kg; Pay attention to the attached operation instruction! Material: steel, black |

2.2 kg

4.8 lb | 19120900 | |

| sealing profile | ||||

| BG-FILCOTEN, sealing profile, BG-FILCOTEN, one, NW200-0, L=760 mm Material: TPE |

0.1 kg

0.2 lb | 19000703 | |

| BG-FILCOTEN, sealing profile, BG-FILCOTEN, one, NW200 40-0, L=1160 mm Material: TPE |

0.1 kg

0.2 lb | 19000704 | |

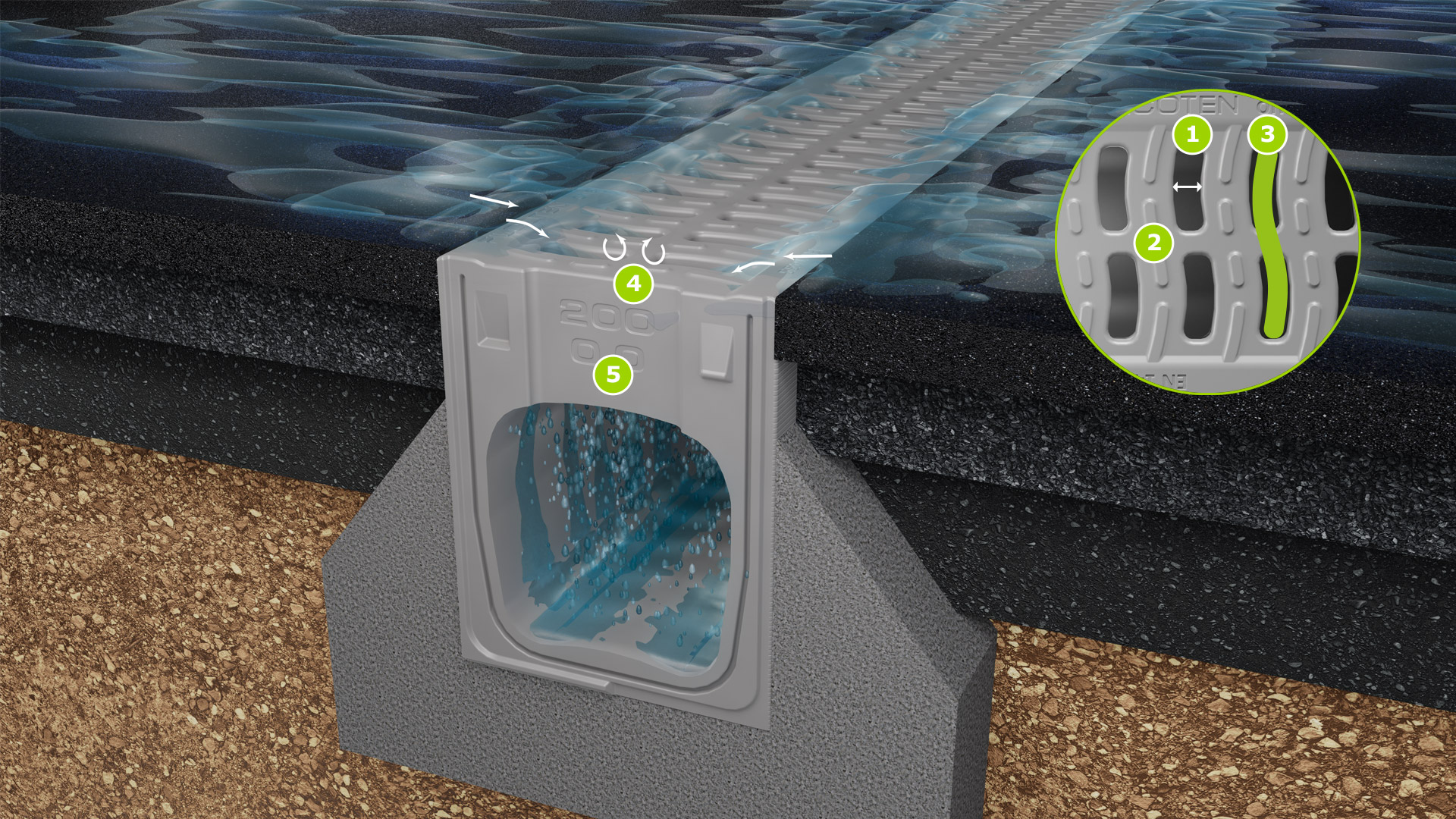

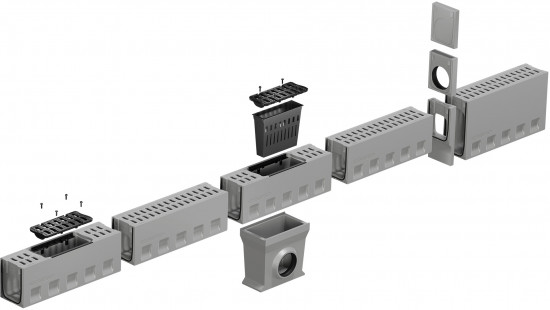

installation BG-FILCOTEN one

The milestone

for heavy loads.

The milestone

for heavy loads.

Front/end cap

- With tongue-and-groove system

- Closure of front sides of the trench drain run

Outlet unit

- Sealed pipe connection DN 200 (KG coupling)

- Left/right rotation

One grating – one design

- Consistent continuation of the S-design for the cast iron grating

- Edge and grating, cathodic dip-coated

- 4-point bolting

- F900 class

Retention & stepped slope

- Overall height 40-0 (20 cm higher than no 0) – for greater hydraulic performance

- Longer trench drain runs possible up to one outlet point

- Suitable for retention (additional volume: 40 l/m)

Your benefits at a glance:

- Outstanding performance in load classes E 600 & F 900.

- Exceptionally sturdy and durable thanks to the FILCOTEN® HPC monolithic structure.

- Innovative design with intelligent features; sits snugly in the concrete bed.

- Simple to install; easy-to-handle sealing system.

- Sustainable, 100 % recyclable, made using 100 % green energy.

Absolutely world class – from E 600 to F 900.

Maintenance unit

- Maintenance access in the style of the trench drain run

- Total length 1000 mm

Basic trench drain NW 200, NW 150

- Standard construction height no 0

- Total length 1,000 mm

Easy access

- Simple cleaning of the outlet unit

- Large outlet opening in the trench drain bottom

- Suspended silt bucket for sump unit

- Total length 1,000 mm

End cap with outlet

- With tongue-and-groove system

- Closure of the run with sealed socket DN 200 (KG coupling)

Adapter cap

- For stepped slope installation

- From height no 0 to 40-0

BG-FILCOTEN

when opposites

attract great things

FILCOTEN HPC (High Performance Concrete) is a material that unites outstanding technical properties with ecological sustainability. The optimised high-density structure of HPC makes it possible to construct extremely stable lightweight drainage channels – but it’s the idea behind it that makes it unique.

Unique concept, revolutionary results.

Our engineers wanted to bring together two extremes:

maximum performance with minimum environmental impact.

Maximum performance, minimal environmental impact.

After intensive development, they finally achieved their goal. FILCOTEN HPC

embodies these opposites, making it unique in the market.

Technology

- FILCOTEN HPC enables lightweight construction

- Quick and easy to lay

- Dimensionally stable, robust concrete elements

- Unsurpassed stability and durability

- Exceptional pressure resistance, well above the requirements in EN 1433

- Maximum resistance to frost and de-icing salt

- UV resistant

- Non-combustible construction material – Class A1

- so no harmful smoke development

- Ideal coefficient of expansion, identical to that of the surrounding concrete

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

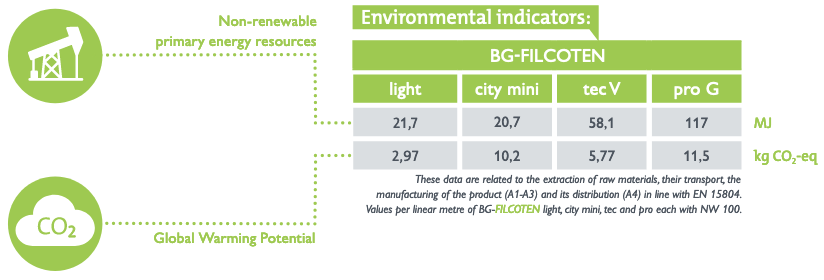

Sustainability

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

- Manufactured with 100% green power

- Resource-efficient manufacturing process

- 100% recyclable, certified

- Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)).

- Environmental & energy management certified under ISO 14001/50001 at the location in Oberwang, Austria

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity, styrene-free

Singularly one,

simply strong.

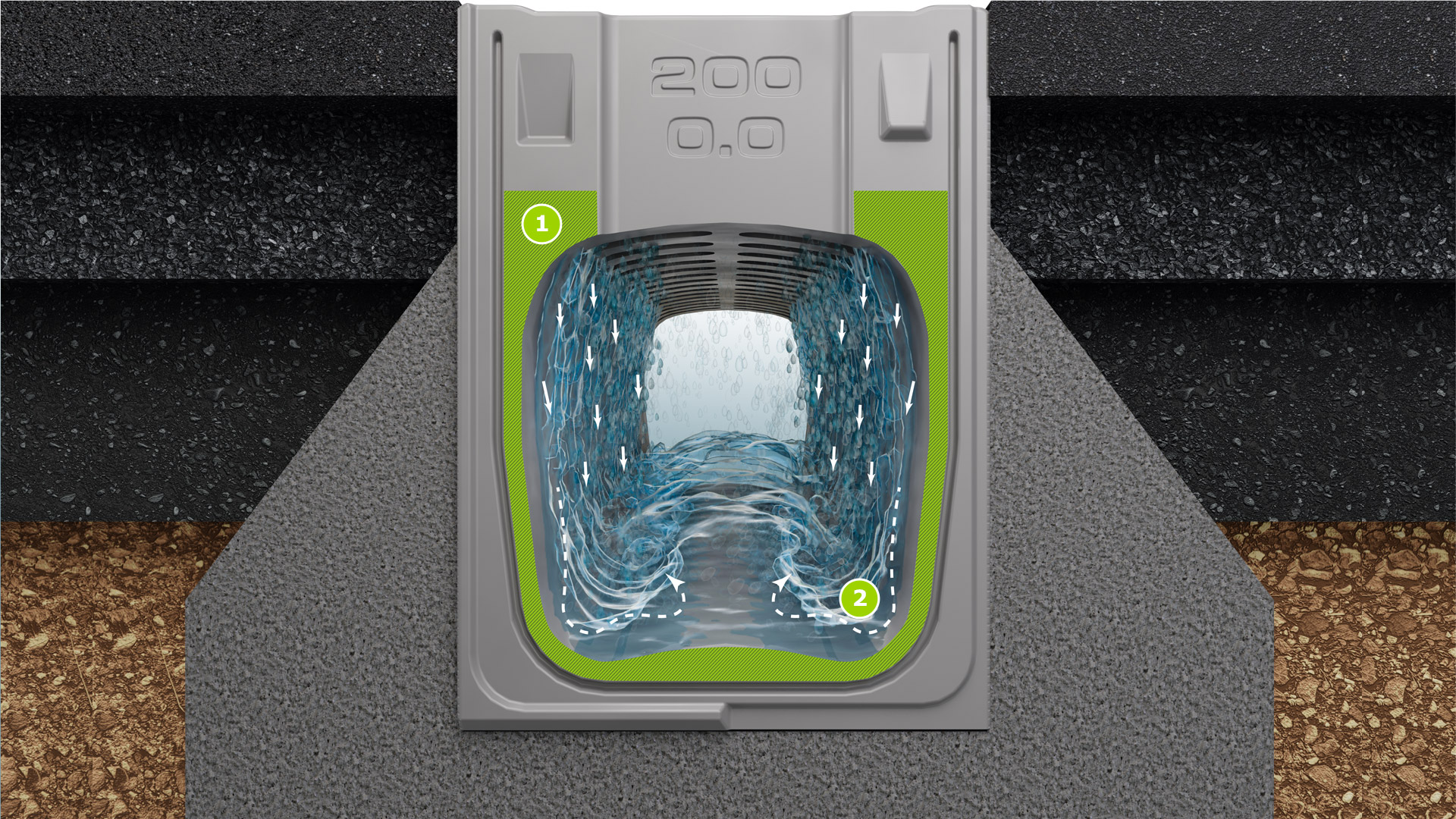

Inlet opening in the trench drain joint

- Inlet opening in the joint with standard slot width for ideal water drainage

Cyclist- and pedestrian-friendly

- Counter-rotating radial arrangement of the inlet openings

- Safe to drive and walk over thanks to the S-design of the double slots

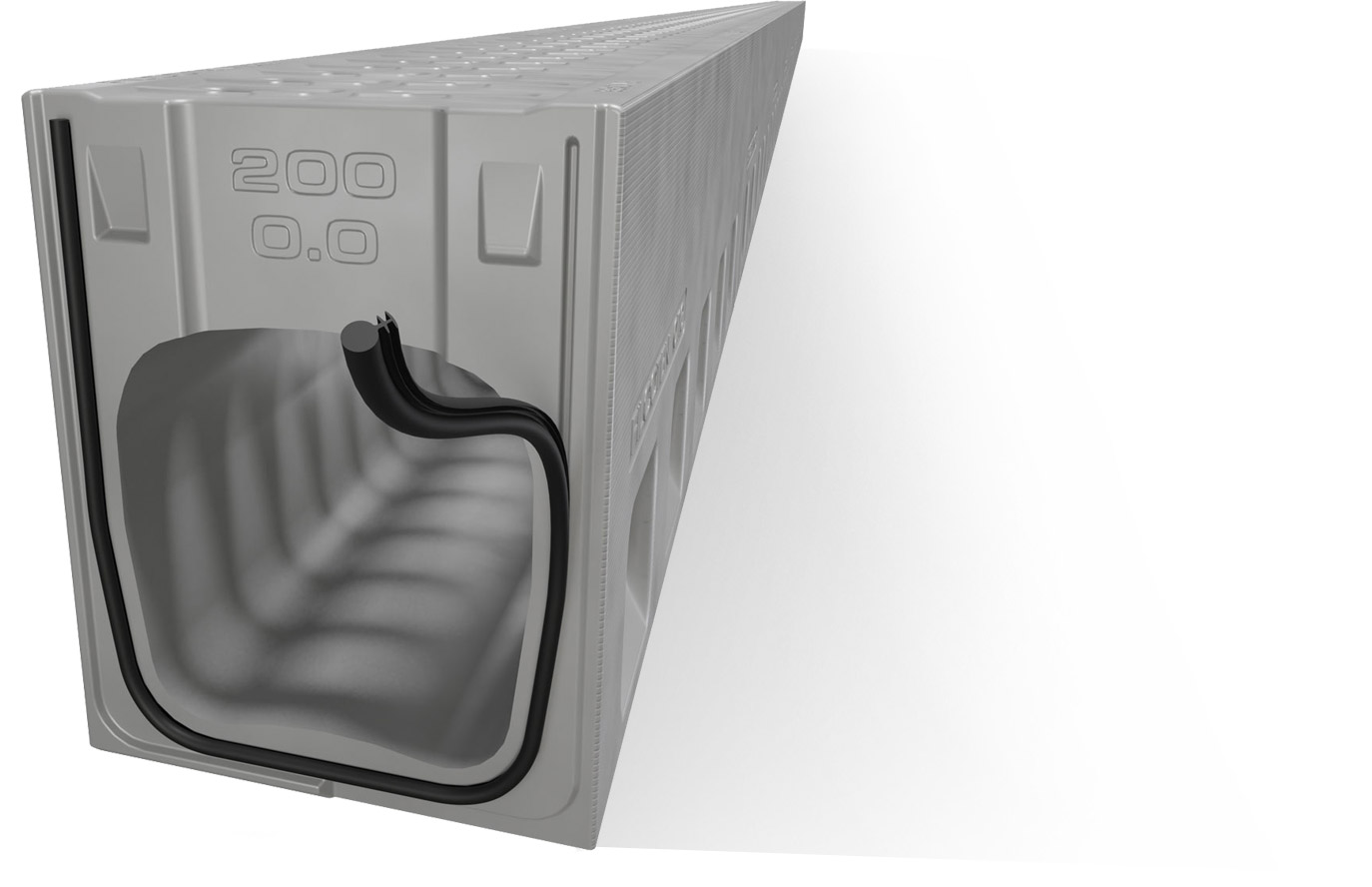

Monolithic structure

- Element made entirely of FILCOTEN® HPC

- Extremely robust and wear resistant

- Ideal for dynamic loads in road traffic

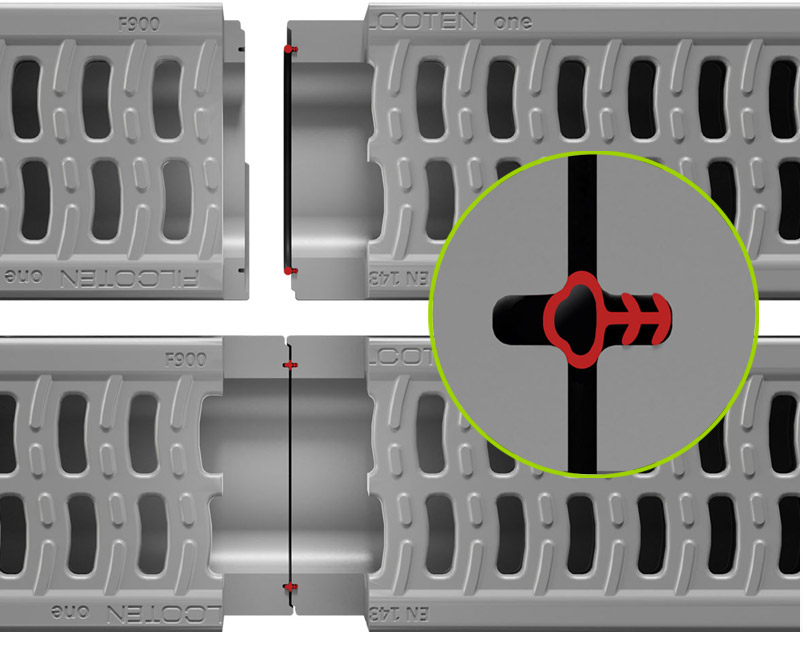

Tongue-and-groove system for installation in either direction

- Non-directional trench drain joint for easy and fast installation

- Interlocking of the groove/tongue/tenon system for accurate, aligned setting of the elements

- Predefined distance in the joint for optimum function of the insertable sealing profile

Highly efficient flume

- Trench drain cross-section with innovative corrugated W-profile design for optimum hydraulic performance on partial and complete filling

- High self-cleaning effect of the W-profile as this causes turbulence in the inflowing water

At one with the surrounding environment

- Fine finished concrete colour and surface quality

Easy-to-handle sealing system

- Preformed groove on the front sides for easy insertion of the sealing profile

- Permanent joint sealing through tight fit of the groove/tongue/tenon system

- Requirements according to EN 1433

Optimised inlet openings

- Slot widths according to EN 1433

- Innovative S-design for efficient rainwater inflow

Extremely durable hold in the concrete bed

- Lateral anchoring pockets for maximum hold in the concrete bed

- Permanent fit in the foundation thanks to identical linear expansion coefficient

- Perfect connection between HPC and concrete

Any

questions?