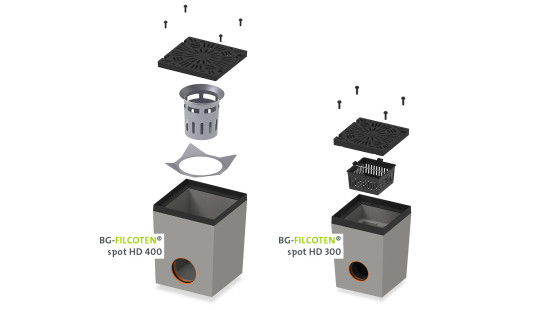

BG-FILCOTEN spot HD

Technical data

| Features | Weight | Item no. | ||

|---|---|---|---|---|

| Verhebeschlaufe | ||||

Lifting loop with thread M10 Material: galvanised steel | _ | 32160 | ||

Made to take

heavy things

lightly.

Made to take

heavy things

lightly.

Inlaid inlet gratings with fiX locking system

- load class E 600

- solid, robust and durable

- KTL-coated ductile iron grating and frame

- quadruple safety screw connection

- insensitive to heat and frost

- large inlet cross-section, high drainage performance

Recessed inlet grating with 4-point bolting

Sediment bucket with insert

Solid cast iron frame

Yard drainage – lower section

Outlet (DN 150)

DN 100 for spot HD 300

DN 150 for spot HD 400

plastic silt bucket

BG-FILCOTEN

when opposites

attract great things

BG-FILCOTEN

when opposites

attract great things

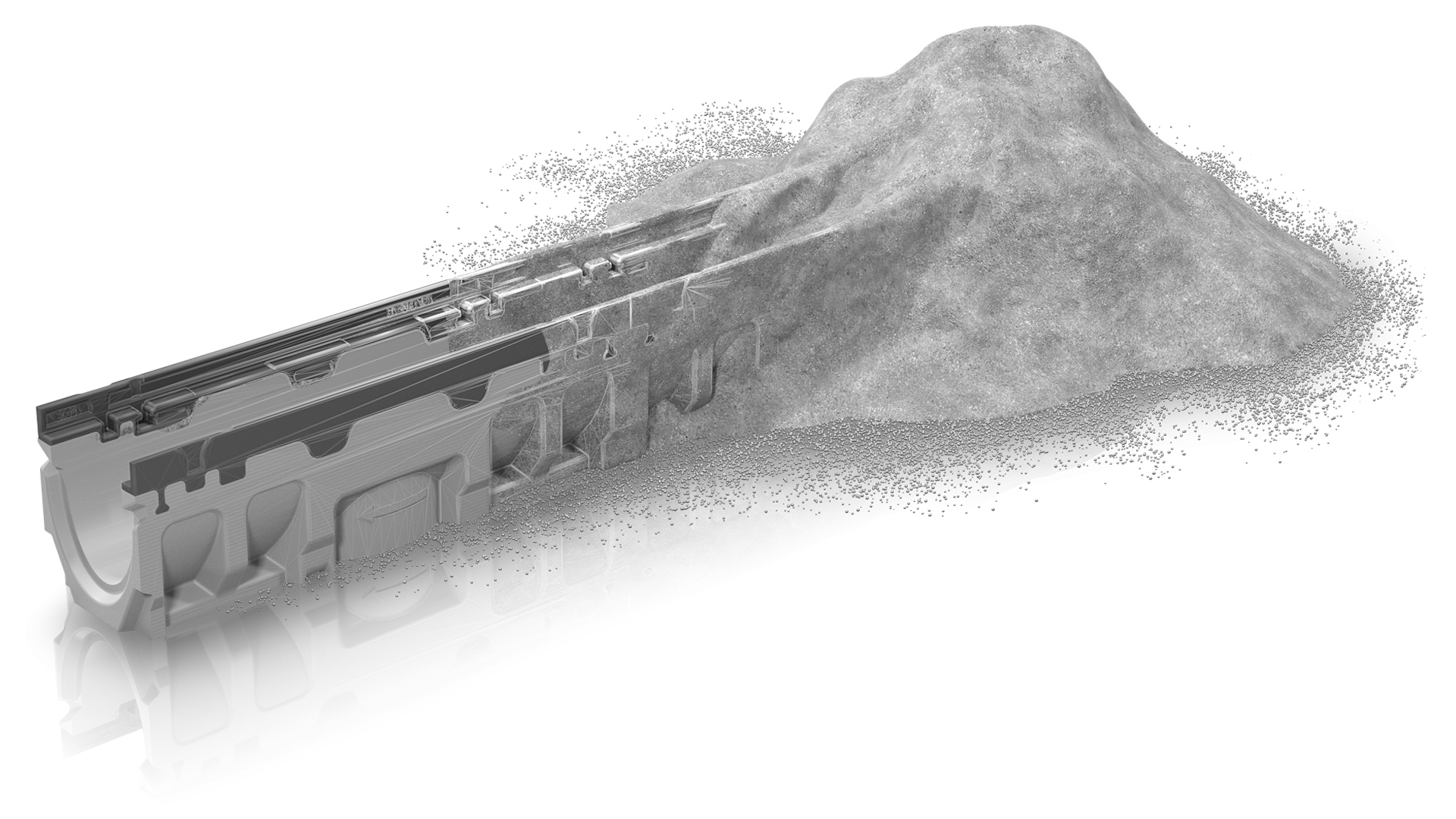

FILCOTEN HPC (High Performance Concrete) is a material that unites outstanding technical properties with ecological sustainability. The optimised high-density structure of HPC makes it possible to construct extremely stable lightweight drainage channels – but it’s the idea behind it that makes it unique.

Unique concept, revolutionary results.

Our engineers wanted to bring together two extremes:

maximum performance with minimum environmental impact.

Maximum performance, minimal environmental impact.

After intensive development, they finally achieved their goal. FILCOTEN HPC

embodies these opposites, making it unique in the market.

Technology

Technology

- FILCOTEN HPC enables lightweight construction

- Quick and easy to lay

- Dimensionally stable, robust concrete elements

- Unsurpassed stability and durability

- Exceptional pressure resistance, well above the requirements in EN 1433

- Maximum resistance to frost and de-icing salt

- UV resistant

- Non-combustible construction material – Class A1

- so no harmful smoke development

- Ideal coefficient of expansion, identical to that of the surrounding concrete

- Low water collection and penetration

- Smooth channel surface for high drainage performance and optimal self-cleaning effect

Sustainability

Sustainability

- Greater ecological transparency under ISO 14040/14044 and EN 15804

- Ideal for sustainable construction projects

- Manufactured with 100% green power

- Resource-efficient manufacturing process

- 100% recyclable, certified

- Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)).

- Environmental & energy management certified under ISO 14001/50001 at the location in Oberwang, Austria

- Certified organic material that meets the strict testing criteria of the Institute for Biologically Sound Construction Rosenheim (IBR) with regard to heavy metals, VOCs, biocides and radioactivity, styrene-free

Any

questions?