Kick-Off in Bratislava

Slovakia’s new National Stadium in Bratislava is located at the same site as its predecessor, but this new facility has a much more sophisticated drainage concept.

... moreApplication areas: platform facade airport (landside) Pedestrian zones landscape construction Garage driveway Garden and landscape construction driveway parking deck Parking area (car) parking garage multi-storey car park block paving Cycle path Slot top Slot channel Swimming pool Sports facility terrace underground car park unobtrusive drainage garage Design discreet drainage

galvanised steel edge

|

stainless steel edge

| ||||||

|---|---|---|---|---|---|---|---|

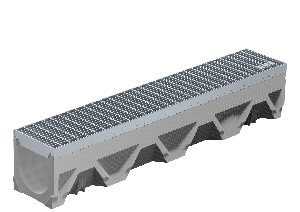

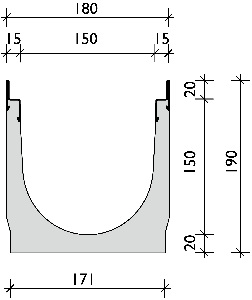

Channel type | Length | Height at channel end | Weight | Item no. | Weight | Item no. | |

| BG-FILCOTEN tec NW 150, without slope | Load class: C 250 | Load class: C 250 | |||||

NW 150 / No. 0 | 1,000 mm | 190 mm |

22.2 kg

10415200

DoP: |

22.2 kg

10415300

DoP: | |||

NW 150 / No. 0 | 500 mm | 190 mm |

12.8 kg

10415250

DoP: |

12.8 kg

10415350

DoP: | |||

NW 150 / No. 10-0 | 1,000 mm | 240 mm |

28.3 kg

10415262

DoP: |

28.3 kg

10415362

product drawing:

dwg

DoP: | |||

NW 150 / No. 10-0 | 500 mm | 240 mm |

16.5 kg

10415252

DoP: |

16.5 kg

10415352

DoP: | |||

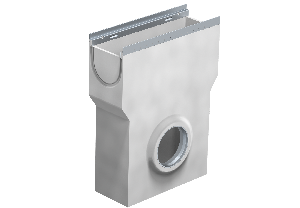

| BG-FILCOTEN tec NW 150, outlet without slope | Load class: C 250 | Load class: C 250 | |||||

| Picture | Load class (kN) | Features | Inlet cross-section (cm²/m) | Weight | Item no. |

|---|---|---|---|---|---|

| Ductile iron elongated bar grating | |||||

C 250

| 710 cm²/m | 5.5 kg | 17015101 | ||

| Ductile iron slotted grating | |||||

B 125

| 515 cm²/m | 4.5 kg | 17015111 | ||

| Plastic grating slotted | |||||

B 125

| L: 500 mm x B: 172 mm x H: 20 mm Material: Plastic Seal: fiX-locking | 550 cm²/m | 1.8 kg | 17015403 | |

C 250

| L: 500 mm x B: 172 mm x H: 20 mm Material: Plastic Seal: fiX-locking | 550 cm²/m | 2 kg | 17015404 | |

| Mesh grating | |||||

B 125

| 1,330 cm²/m | 4.6 kg | 17015220 | ||

B 125

| 1,285 cm²/m | 2.4 kg | 17015221 | ||

C 250

| 1,280 cm²/m | 6.9 kg | 17015222 | ||

C 250

| 1,240 cm²/m | 3.6 kg | 17015223 | ||

C 250

| 1,280 cm²/m | 6.9 kg | 17015322 | ||

C 250

| 1,240 cm²/m | 3.6 kg | 17015323 | ||

| Perforated grating | |||||

C 250

| 195 cm²/m | 10 kg | 17015228 | ||

C 250

| 195 cm²/m | 5 kg | 17015229 | ||

C 250

| 195 cm²/m | 7 kg | 17015328 | ||

C 250

| 195 cm²/m | 3.5 kg | 17015329 | ||

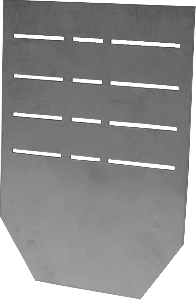

| slot top asymetric | |||||

C 250

| 125 cm²/m | 6.7 kg | 17115243 | ||

C 250

| 120 cm²/m | 7 kg | 17116204 | ||

C 250

| 125 cm²/m | 3.4 kg | 17115244 | ||

C 250

| 120 cm²/m | 3.6 kg | 17116205 | ||

C 250

| 125 cm²/m | 6.7 kg | 17115343 | ||

C 250

| 120 cm²/m | 7 kg | 17116304 | ||

C 250

| 180 cm²/m | 7.9 kg | 17116307 | ||

C 250

| 125 cm²/m | 3.4 kg | 17115344 | ||

C 250

| 120 cm²/m | 3.6 kg | 17116305 | ||

C 250

| 180 cm²/m | 4 kg | 17116308 | ||

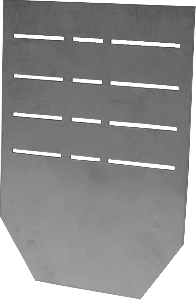

| maintenance unit asymmetric | |||||

C 250

| 125 cm²/m | 6 kg | 17115281 | ||

C 250

| 120 cm²/m | 6.1 kg | 17116206 | ||

C 250

| 125 cm²/m | 6 kg | 17115381 | ||

C 250

| 120 cm²/m | 6.1 kg | 17116306 | ||

C 250

| 180 cm²/m | 6.9 kg | 17116309 | ||

| Features | Weight | Item no. | ||

|---|---|---|---|---|

| universally | ||||

| BG-FILCOTEN, tec KIT NW 150 V, sump unit galv. steel edge, silt bucket, pipe coupl. DN 150 consisting of: 10415291 - Filcoten tec sump unit 22516 - silt bucket Material: FILCOTEN HPC | 40.3 kg | 10415292 | |

| BG-FILCOTEN, tec KIT NW 150 E, sump unit, stainl. steel edge, silt bucket, pipe coupl. DN 150, delivery time on request consisting of: 10415391 - Filcoten tec sump unit 22516 - silt bucket Material: FILCOTEN HPC | 40.3 kg | 10415392 | |

| construction time barrier | ||||

BG construction time barrier, slot SW 12,5/15 (2x6), length 1000, wood (slot top - double slot 2x6) Attention: store in a dry place closed Material: wood | 0.1 kg | 37962 | ||

| Silt bucket | ||||

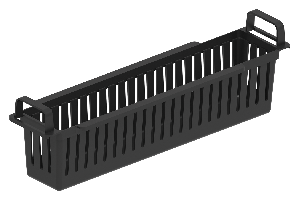

| BG-FILCOTEN, silt bucket for FILCOTEN, sump unit NW 150, plastic (light, tec, pro) Material: HDPE | 0.3 kg | 22516 | |

| odour trap | ||||

| BG PVC syphon odour trap (sewer pipes) DN 150/87° consisting of: 4 pcs. 30031 - PVC-pipe-elbow DN 150/87° Material: PVC | 3.9 kg | 30030 | |

| BG-FILCOTEN, drain trap for sump unit DN 150 for backfitting (light, tec, pro) Material: PVC | 0.2 kg | 30057 | |

| front cap | ||||

| BG-FILCOTEN, front cap NW 150, closed, galvanized (light, tec, pro No. 0-10, pro mini H170)" Material: galvanised steel | 0.6 kg | 19015230 | |

| BG-FILCOTEN, front cap NW 150, closed, stainless steel (light, tec, pro No. 0-10 pro mini H170) Material: stainless steel 1.4301 | 0.6 kg | 19015330 | |

| end cap | ||||

| "BG-FILCOTEN, End cap NW 150, outlet DN150, galvanized (tec, pro No. 0-10 pro mini H170)" Material: galvanised steel | 0.6 kg | 19015231 | |

| BG-FILCOTEN, End cap NW 150, outlet DN150, stainless steel (tec, pro No. 0-10 pro mini H170) Material: stainless steel 1.4301 | 0.6 kg | 19015331 | |

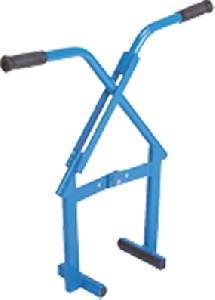

| installation chairs | ||||

BG-FILCOTEN, KIT, installation chair lower part, size 2, incl. nuts NW150: light, tec, pro NW200: tec, pro Material: galvanised steel | 1.3 kg | 19020926 | ||

BG-FILCOTEN, KIT, installation chair upper part, size 2, incl. bolting material NW150: light, tec, pro NW200: tec, pro Material: galvanised steel | 0.5 kg | 19020927 | ||

BG-FILCOTEN SET, composite installation support kit NW100 to NW300 Material: Plastic | 0.7 kg | 19000401 | ||

| locking device for gratings | ||||

| BG-FILCOTEN, anti-vandalism locking device NW 150 (FILCOTEN, tec, pro) Material: stainless steel 1.4301 | 0.1 kg | 32088 | |

| opening tool | ||||

BG opening tool for maintenance unit Material: galvanised steel | 0.1 kg | 13399 | ||

| BG-Dichtsystem | ||||

BG applicator gun 450 ml - 600 ml | 0.5 kg | 31203 | ||

BG sealing mass 1K - Standard (PRO 3), grey, 600 ml | 0.6 kg | 31300 | ||

BG sealing mass 1K - Special (Tank N), grey, 600 ml | 0.6 kg | 31301 | ||

BG Primer, 250 ml | 0.3 kg | 31302 | ||

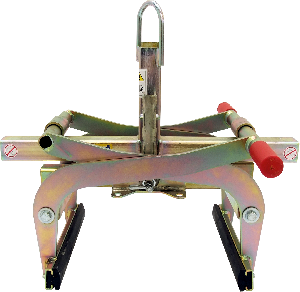

| lifting grab | ||||

| lifting grab channels and cable troughs, max. load 250 kg | 18 kg | 80018 | |

| lifting grab channels and cable troughs, max. load 600 kg max. load: 600 kg opening width: 50 - 600 mm, grabs from the outside; Pay attention to the attached safety instructions! | 29 kg | 80019 | |

| lifting grab for manual laying | 4.5 kg | 80002 | |

Slovakia’s new National Stadium in Bratislava is located at the same site as its predecessor, but this new facility has a much more sophisticated drainage concept.

... moreWith BG-BLACKLABEL we offer you a range of design gratings that combine top-class design with the usual BG-performance. Thanks to state-of-the-art production technology, there are no limits to your creativity ...

... moreOriginally it was the České srdce ground, built in 1925 by what was then the first-division Vienna football club SK Slovan, and in 1973 it became home to FK Austria Wien – thus Generali Arena looks back not only on a long football tradition but also on a history of expansion and new buildings. The stadium’s recent renovation, carried out from 2016 to 2018, represents a major step forward, including in terms of sustainability.

... more

installation description | |

|---|---|

| BG-FILCOTEN tec | |

| FCT-tec-installation-EN.doc | DOC |

| FCT-tec-installation-EN.pdf | |

| installation-rebar-support-EN.pdf | |

| installation-rebar-support-EN.docx | DOCX |

installation detail | |

|---|---|

| BG-FILCOTEN tec | |

| FCT-tec-NW150-installation-detail.pdf | |

tender text | |

|---|---|

| BG-FILCOTEN tec | |

| FCT-tec-NW150-tender-text-EN.doc | DOC |

| FCT-tec-NW150-tender-text-EN.pdf | |

data sheet | |

|---|---|

| BG-FILCOTEN tec | |

| FCT-tec-NW150-data-sheet.pdf | |

| FCT-tec-NW150-data-sheet.dwg | DWG |

DoP (declaration of performance) | |

|---|---|

| BG-FILCOTEN tec | |

| DoP-104-BG-FCT-tec-V-E-EN.pdf | |

product drawing | |

|---|---|

| BG-FILCOTEN tec | |

| TD-10415200-10415300-FCT-tec-V-E-NW150-Nr.0.pdf | |

| TD-10415200-10415300-FCT-tec-V-E-NW150-Nr.0.dwg | DWG |

| TD-10415250-10415350-FCT-tec-V-E-NW150-Nr.0-500mm.pdf | |

| TD-10415250-10415350-FCT-tec-V-E-NW150-Nr.0-500mm.dwg | DWG |

| TD-10415270-10415370-FCT-tec-V-E-NW150-Nr.0-mA.pdf | |

| TD-10415270-10415370-FCT-tec-V-E-NW150-Nr.0-mA.dwg | DWG |

| TD-10415262-10415362-FCT-tec-V-E-NW150-Nr.10-0.pdf | |

| TD-10415252-10415352-FCT-tec-V-E-NW150-Nr.10-0-500mm.pdf | |

| TD-10415252-10415352-FCT-tec-V-E-NW150-Nr.10-0-500mm.dwg | DWG |

| TD-10415262-10415362-FCT-tec-V-E-NW150-Nr.10-0.dwg | DWG |

| TD-10415272-10415372-FCT-tec-V-E-NW151-Nr.10-0-mA.pdf | |

| TD-10415272-10415372-FCT-tec-V-E-NW151-Nr.10-0-mA.dwg | DWG |

BIM (Building Information Modeling) | |

|---|---|

| 1-BIM-REVIT.zip | ZIP |

| 2-BIM-open-source.zip | ZIP |

Additional safety

aspects for channel & grate.

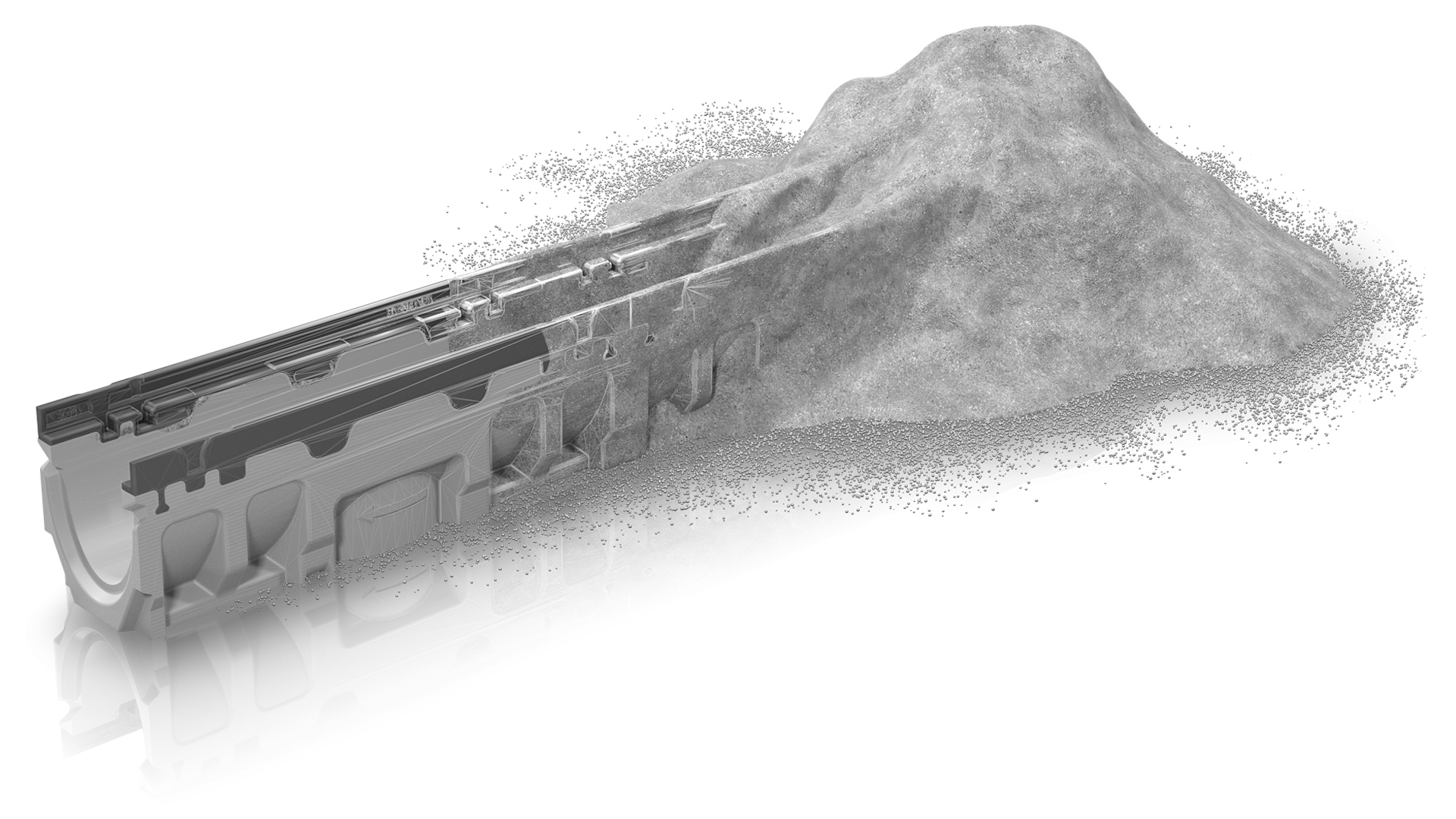

BG-FILCOTEN

when opposites

attract great things

FILCOTEN HPC (High Performance Concrete) is a material that unites outstanding technical properties with ecological sustainability. The optimised high-density structure of HPC makes it possible to construct extremely stable lightweight drainage channels – but it’s the idea behind it that makes it unique.

Unique concept, revolutionary results.

Our engineers wanted to bring together two extremes:

maximum performance with minimum environmental impact.

Maximum performance, minimal environmental impact.

After intensive development, they finally achieved their goal. FILCOTEN HPC

embodies these opposites, making it unique in the market.

Technology

Sustainability

Any

questions?

Select a product to carry out the hydraulic averaging.

For a precise hydraulic calculation that takes account of the local conditions, please contact our Technical Support at sales.int@bg-graspointner.com.

Select a product to search for the references.