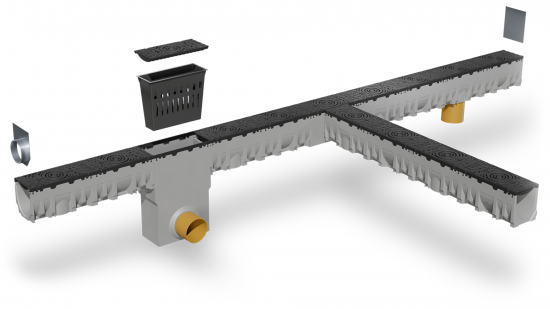

<div class="moduleOverviewItem-title">Three edge variants</div>

Edges made of galvanised steel, stainless steel or cast iron are available.

+

<div class="moduleOverviewItem-title">Channel geometry/smooth surface</div>

The optimised channel geometry and smooth surface of FILCOTEN HPC ensure maximum flow and self-cleaning effects

+

<div class="moduleOverviewItem-title">Safety seam</div>

A sealable safety seam enables a sealed connection between the individual segments.

+

<div class="moduleOverviewItem-title">Standard outlets</div>

Every channel body without an inner slope has a vertical outlet option.

+

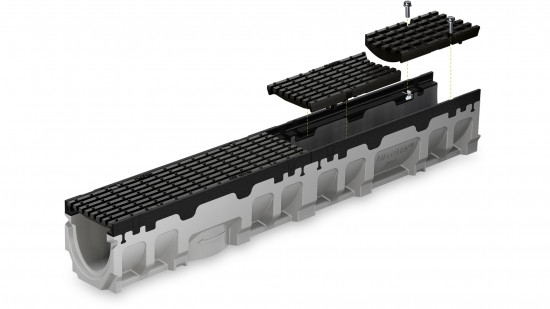

<div class="moduleOverviewItem-title">Bolted iron grip</div>

As an alternative to the fiX locking system, cast iron gratings in cl. D or E (see table depending on the nominal width) can be bolted to the cast iron edge with 4-point bolting. All fittings are supplied as a kit. Our fittings are simple and easy to change. The cage nuts are replaceable and securely fit in the cast iron edge.

+

<div class="moduleOverviewItem-title">Secure hold for the grating</div>

The intelligent fiX locking system enables the simple four-point quick-locking of the grating in the channel. The integrated pins to prevent longitudinal shifting provide added safety.

+

<div class="moduleOverviewItem-title">Perfect channel installation</div>

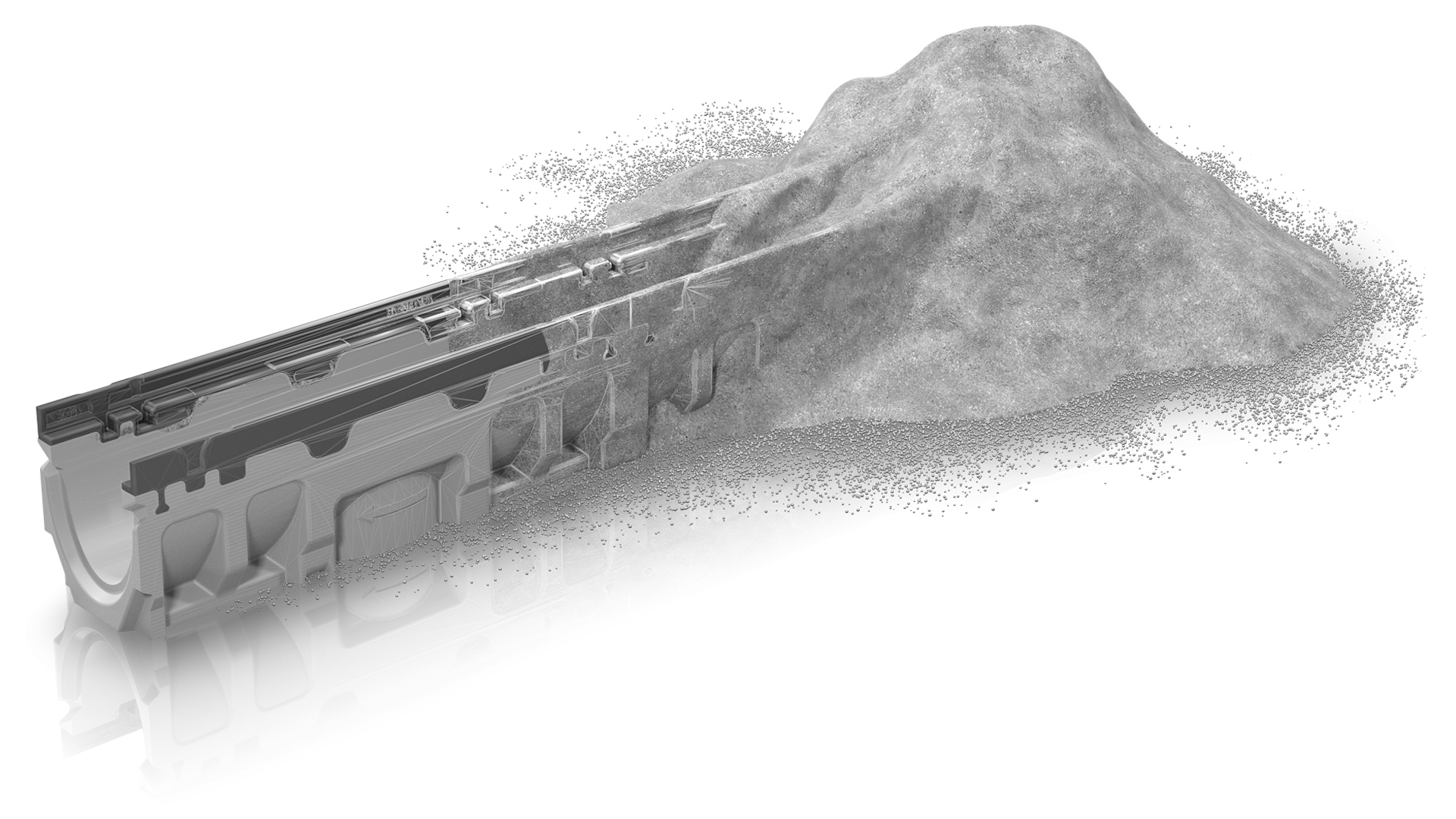

Anchoring pockets ensure a secure bond and anchoring of the channel in the concrete foundation.

+

<div class="moduleOverviewItem-title">Innovative production technology</div>

The innovative FILCOTEN HPC production and moulding technology made it possible to design anchoring pockets for a concrete channel body for the very first time, ensuring an even better hold in the concrete bed.

+

<div class="moduleOverviewItem-title">Stable thanks to the FEM analysis</div>

The FEM analysis is a computer-assisted process which simulates exactly which structures withstand which loads. The more accurately the effect of the forces is known, the easier it is to choose the optimal solution.

+

<div class="moduleOverviewItem-title">Advantages at a glance</div>

- Three edge variants: Steel, Stainles Steel or cast - optimised channel geometry and smooth surface - sealable safety seam

Advantages at a glance