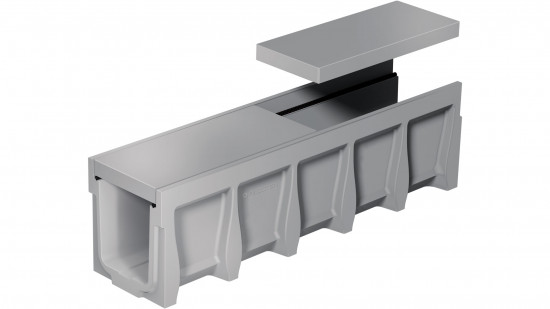

BG-RAIL FILCOTEN cable trough

With its lightweight design, exceptional stability and low environmental impact, the BG-RAIL FILCOTEN cable trough opens a whole new chapter in railway construction. The perfectly coordinated installation system makes for fast and precise preparation of the cable route. The lightweight design makes it much easier to install and handle. Good for the environment and your CO2 footprint. FILCOTEN HPC combines outstanding material properties with exceptional sustainability. This puts the new FILCOTEN cable trough into a class of its own when it comes to environmental friendliness. 100 percent recyclable – quality class U-A, IBR-certified organic material and low greenhouse gas emissions protect nature and improve your CO2 footprint.

Technical data

Channel material

FILCOTEN HPC

Length

1,000 mm

Width

250 mm, 345 mm

Height at channel end

290 mm

Application areas: Rail station platform railway route cable shaft cable route Cable trough

Download category

Optimises every cable route

and your CO2 footprint.

Optimises every cable route

and your CO2 footprint.

<div class="moduleOverviewItem-title">Lived sustainability: FILCOTEN HPC (High Performance Concrete)</div>

<ul> <li>Mineral high-performance concrete (dense, low-capillary, optimised microstructure)</li> <li>Extremely durable, stable and UV-resistant</li> <li>Extremely resistant to frost, de-icing salt, oil, petrol</li> <li>100% recyclable – quality class U-A (2)</li> <li>Certified environmental and energy management according to ISO</li> <li>14001 or 50001 at the Oberwang site, Austria</li> <li>IBR-certified (1), tested for: VOCs, styrene (3) and BTEX, heavy metals, radioactivity</li> </ul>1) Meets the strict criteria outlined by the Rosenheim Institute for Construction Biology (IBR). 2) Quality class U-A (certified by the Bautechnische Versuchs- und Forschungsanstalt Salzburg (bvfs)). 3) No use of synthetic resins.

+

<div class="moduleOverviewItem-title">Maximum lateral stability</div>

The solid ribs on the side walls ensure maximum stability.

+

<div class="moduleOverviewItem-title">Prevents shifting at the transition</div>

With the tongue-and-groove system, the troughs are installed from top to bottom. This helps avoid any sideways shifting and prevents grit from entering the cavity.

+

<div class="moduleOverviewItem-title">The benefits at a glance:</div>

<ul> <li>Lightweight yet stable component</li> <li>Environmentally friendly, 100% recyclable</li> <li>Quicker installation (manual installation possible) – less track obstruction time</li> <li>High dimensional accuracy and straightness with the tongue-and-groove system and trough installation from above</li> <li>The BG-RAIL FILCOTEN cable trough is lighter, narrower and more compact than conventional troughs. The easier and faster creation of mitre cuts saves time when diverting the run around pylons.</li> </ul>

The benefits at a glance

<div class="moduleOverviewItem-title">Trench belt</div>

A trench belt can be deployed when needed and ensures a proper fit of the cover.

+

<div class="moduleOverviewItem-title">Smooth surface</div>

The smooth internal surface of the BG-RAIL FILCOTEN cable trough makes it easier to pull in the cable strands.

+

<div class="moduleOverviewItem-title">Recess edge – outer edge of the trough</div>

The upper edge serves as a guide to level the backfill material when creating paths.

+

<div class="moduleOverviewItem-title">Verified LCA (life cycle assessment)</div>

<ul> <li>Reduced greenhouse gas emissions</li> <li>Manufactured with 100% green power</li> <li>Resource-efficient manufacturing process</li> </ul>

+

<div class="moduleOverviewItem-title">Cable trough cover</div>

The cable trough cover protects cables from damage and harsh weather. All cable trough covers are produced with or without fibre reinforcement.

+

<div class="moduleOverviewItem-title">Anchoring pockets</div>

The innovative FILCOTEN HPC production and moulding technology made it possible to design anchoring pockets for a concrete trough body to ensure an even better hold in the ballast bed.

+

Any

questions?